|

Consultants in Lean Manufacturing & Manufacturing Strategy (Our Online Store is back with new convenience and a new look!) |

|

|

|

|

The free newsletter of Lean Manufacturing Strategy

Books & Videos

The Strategos Guide To Value Stream and Process Mapping goes far beyond symbols and arrows. In over 163 pages it tells the reader not only how to do it but what to do with it. More info... Strategos Guide to Value Stream & Process Mapping Also... |

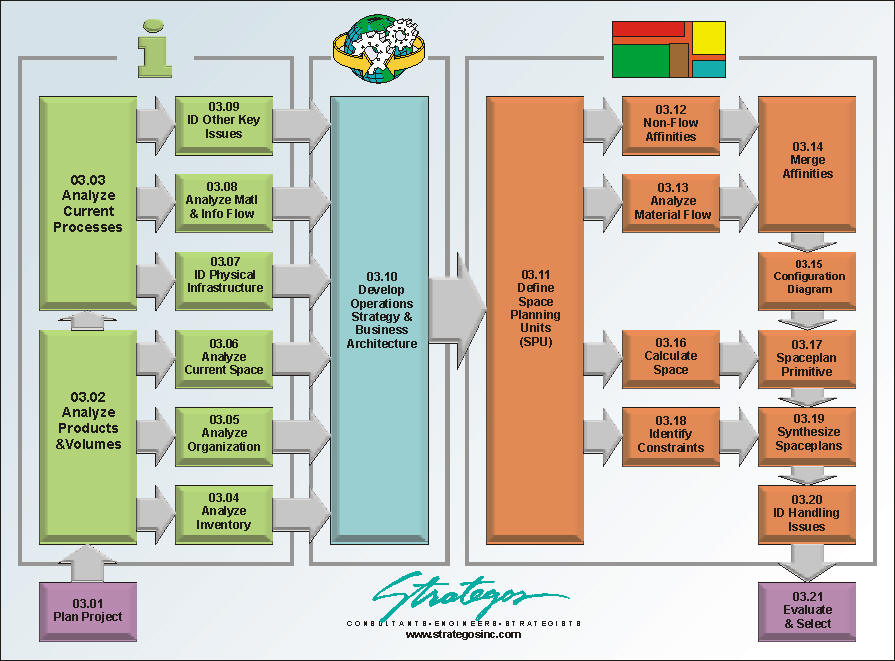

Generalized Macro-Layout Design Procedure This procedure will develop excellent layouts with a high level of consensus. It saves time and frustration and will minimize backtracking.

Typical Macro-Layout This macro-layout is based on a manufacturing strategy that uses workcells for the several thousand components that the company machines for pump. The hydrant and valve operation use dedicated production lines. Some operations within the pump department, such as testing, are centralized in functional areas because of the massive test equipment required. | ||||

|

■ ■ ■ ■ ■ ■ ■ |

|

Contact Webmaster |

Strategos-International: North America - Europe - Australia |

|

SEP 2007 ©_Permissions