Why Draw Pictures?

A factory is enormously complex. Only visuals convey enough information to understand the

pieces, relationships, hidden waste and time-domain behavior.

Visualization brings a deep understanding and major breakthroughs in productivity and other

performance. It leads to consensus on systemic problems and remedies. While finished charts

communicate information about a situation, the real value is the mapping itself. This is where

insights grow, paradigms shift and consensus builds.

Value Stream and

Process Maps take different perspectives,

but, the work they visualize is the same. Both have a place

Value Stream Maps

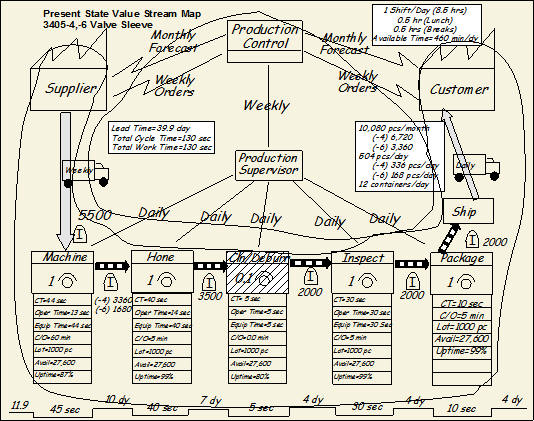

These show major process steps and often take a broader and wider view. They may group a wide

variety of products into a single "value stream." Here is an example:

|

The

Strategos Guide To The

Strategos Guide To

Value Stream &

Process Mapping

Quarterman Lee's latest book on

Value Stream Mapping and Process Mapping goes far beyond symbols and arrows. It tells

the reader not only how to do it

but what to do with it. More

Info >>

|

|

Process Maps (charts)

These are also known as "Process Charts" or "flow Process Charts". They trace the sequence of

events for a single product. While they can be done at any level, the most useful charts are

quite detailed. This is important because most waste is at a micro- level.

Frank Gilbreth's symbology, which we

prefer, is simple and visual. One does not need the Rosetta Stone to decipher hieroglyphics. It

dramatically displays waste. In this example, all but the green circles are waste.

Process mapping is a great tool for Kaizen events.

Their simplicity makes them ideal when training time is limited.

Which To Use?

The short answer is both:

|