|

The free newsletter of Lean Manufacturing Strategy

Lean Briefing Archives

Books & Videos

The Strategos Guide To Value Stream and Process Mapping goes far beyond symbols and arrows. In over 163 pages it tells the reader not only how to do it but what to do with it.

More info...

Strategos Guide to Value Stream & Process Mapping

Also...

Guide to Cycle Counting

Facilities & Workplace Design

Warehouse Planning Guide

Human Side of Lean Video

|

|

Ergonomics & Lean

Some Basics & How To Use Them

|

What Is

Ergonomics? What Is

Ergonomics?

Ergonomics studies work as it relates to the human body and its limits. The usual goal is

maximum output without physical harm. The most prevalent ergonomic related injuries are

musculoskeletal; either from repetition, overload, awkward positions or some combination.

Physiology,

biomechanics,

anthropometrics, worker selection and

man-machine allocation are the areas of ergonomics most useful to manufacturing and industrial

engineers.

Ergonomics & Lean Manufacturing

Ergonomics is most important at the level of workcell

design and workstation design. By their very

nature, well-designed cells relieve many of the risk factors associated with traditional

workstations and functional layouts. For example, workcells often rotate workers through an

entire process on each cycle. This reduces repetition and static postures. Workstations also

have a direct influence on musculoskeletal disorders.

|

Branches of Ergonomics

Physiology

Physiology studies this energy conversion

process. It can reduce fatigue and improve worker stamina.

Biomechanics

Biomechanics studies the mechanical forces

in human movement. Its principles can help to minimize damage to muscles, joints, and tissues.

This damage may come from a one-time force, such as lifting an object that is too heavy or

moving an object from an awkward position. Damage also can come from an accumulation of small,

repetitive forces--Cumulative Trauma Disease (CTD).

Anthropometry

Anthropometry studies the dimensions, weights, and

strengths of the human body. This data helps to design effective workstations and spaces.

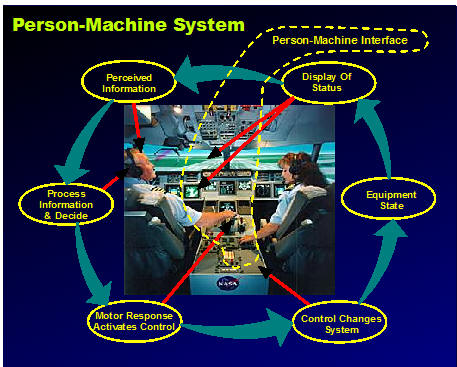

Allocation of Functions

Allocation divides work between people and

machines. It determines, to a large extent, the quality of work experience. A well-thought-out

allocation optimizes the interaction of people and machine elements. Allocation also relates to

Socio-Technical Systems (STS).

|

Physiology

|

In

some respects, the body is analogous to an automobile. In the human machine, muscles are both

cylinders and pistons, and bones and joints are the gears. The muscles oxidize nutrients (fuel)

and give up energy, while generating metabolic byproducts (waste). Physiology studies this

process. In

some respects, the body is analogous to an automobile. In the human machine, muscles are both

cylinders and pistons, and bones and joints are the gears. The muscles oxidize nutrients (fuel)

and give up energy, while generating metabolic byproducts (waste). Physiology studies this

process.

Two categories of physiological demands usually are relevant during work: static and dynamic.

Static work occurs when the body is in a stationary position for an extended period. Dynamic

work involves considerable movement.

The musculoskeletal system is unsuited for prolonged static work because the body cannot

supply fresh nutrients to the stressed tissues. In addition, waste products remain at the

stressed site. Muscles and tendons can inflame. Even at static loads as low as 30 percent of

maximum strength, fatigue develops rapidly.

|

In dynamic work nutrients and waste products move to and from the muscles. Consequently, the

muscles can work for extended periods if the maximum load on the body is significantly less than

the maximum static capability.

Endurance usually limits dynamic work when loads are not extreme. Toyota uses this effect by

designing workcells that require considerable walking and movement. This reduces static work

with a slight increase in dynamic work. There are many other advantages such as allowing

work balance through circulation.

Usually, tasks should not require operators to exert more than 30 percent of their maximum

muscle force in a prolonged or repetitive way. All muscular exertions beyond 50 percent of the

maximum level should be avoided.

|

Biomechanics

|

Biomechanics studies the mechanical forces in human movement. Its principles help to

minimize damage to muscles, joints, and tissues.

One-time forces that are simply too great for the joint or muscle can create damage. However,

workers are usually aware of direct, one-time overloads. The effects are felt immediately,

perhaps before damage has occurred. Several factors shown to the right can multiply forces and

aggravate damage. The worker is often unaware of these aggravating factors.

Ignoring biomechanical considerations is the most common cause of work-related

musculo-skeletal disorders such as Carpal Tunnel Syndrome and tendonitis.

|

Aggravating Factors

Extreme Joint Position- Joints placed in extreme positions or angles amplify many biomechanical forces. Thus a load

that seems very manageable to the worker may actually cause serious damage. The worker may not

be aware of this damage until too late. Extreme Joint Position- Joints placed in extreme positions or angles amplify many biomechanical forces. Thus a load

that seems very manageable to the worker may actually cause serious damage. The worker may not

be aware of this damage until too late.

Repetition- Highly repetitive movements without time for rest and healing can create damage even when the

forces are quite small. The worker is often unaware of the damage for days or weeks.

|

Anthropometry

|

Human dimensions, weights and strengths are the province of anthropometry. Workstation designers

need this data to avoid putting workers in risky positions where they must reach too far or sit

to low. Such risk positions amplify the forces on the body and increase the probability of

repetitive stress disorders. Sometimes risky positions can cause undue fatigue as well.

Humans vary significantly in size and build. In some situations, it is

sufficient to design for the smallest or largest likely dimension. In other situations,

adjustable benches, chairs or devices are required for the full range of people.

Our page on Selected Anthropometric Dimensions shows some

of the more commonly used dimensions as well as the normal ranges.

|

|

What should machines do?; What should people do?

These are important decisions in the design of any workstation, manufacturing system or

process. Such decisions affect product quality, flexibility, overhead cost, worker health and

the economic viability of the process. The list below shows some of the relevant factors for making such decisions.

An Over-Automation Example

In the early days of the Mercury space program, NASA engineers attempted to automate

almost every aspect of space flight. The original Mercury 7 astronauts vehemently objected to

their proposed role as mere passengers. They called it "Spam In A Can." As a result, Mercury and

subsequent manned spacecraft designs assigned significant roles and tasks to the astronauts. The

unique value that humans bring to certain tasks was demonstrated dramatically with the Apollo 13

mission.

This is an example of the strong tendency in some organizations to "over-automate" and assign

most tasks to use machines. However, insufficient automation is equally ineffective. Much depends on

the state of the technology and the relative economics of automation and labor.

People Are Good At-

|

Machines & Computers Are Good At

-

Simple, Quantitative, Accurate

Information

-

Simple, Straight-Forward Decisions

-

Sharply Defined Processes

-

No Customer Interfaces

-

Repetition

-

Short Cycle times

-

Long Runs

-

High Volume

-

High Precision

-

Heavy Loads/Large Forces

|

|

|

|

|