Lesson 3

machining mill tools & operations

FIGURE 1

![]() Lesson 3 explains different tools/purposes, cutting operations,

and

proper work/camping setup. In figure 1 shows the main tools/holders in

DASL Index. This tutorial is largely based on the

HAAS Workholding

&

tooling tutorial.

Lesson 3 explains different tools/purposes, cutting operations,

and

proper work/camping setup. In figure 1 shows the main tools/holders in

DASL Index. This tutorial is largely based on the

HAAS Workholding

&

tooling tutorial.

Section 1 - Tool Holders

Section 2 - Cutting Tools

Section 3 - Operations

Section 1 - Tool Holders

![]() Selecting the right tool holder for the job is as important as selecting

the

right cutter for the job. You should always use the shortest tool holder

possible for all machining applications. In addition, the tool should be

set

into the tool holder as far as possible. This will increase the tool

holder's

grip on the tool and reduce vibration. The shorter the distance from the

spindle

nose to the tool tip, the more rigid your setup will be. Increased

rigidity

means less vibration when cutting.

Selecting the right tool holder for the job is as important as selecting

the

right cutter for the job. You should always use the shortest tool holder

possible for all machining applications. In addition, the tool should be

set

into the tool holder as far as possible. This will increase the tool

holder's

grip on the tool and reduce vibration. The shorter the distance from the

spindle

nose to the tool tip, the more rigid your setup will be. Increased

rigidity

means less vibration when cutting.

For more information on toolholder design and varieties , please consult

the

Tormach

Tooling System Manual: Page 4

Section 2 - Cutting Tools

![]() When selecting cutting tools for a job, the first thing to consider is

what type

of operation needs to be performed. Here is a quick description of the

basic

cutting tools most often used in milling operations.

When selecting cutting tools for a job, the first thing to consider is

what type

of operation needs to be performed. Here is a quick description of the

basic

cutting tools most often used in milling operations.

Drill

A twist drill is used to create a round, cylindrical hole in a

workpiece.

Drilled holes can be "through holes" or "blind holes". A "blind hole" is

not cut

entirely through a workpiece. Quite often, an engineering blueprint will

specify

a drilled hole to be drilled to "full diameter depth." This means that

the hole

diameter must be a specified depth without regard to the angled tip of

the

drill. When you measure your tool length offset, you are measuring the

length of

the drill and its tip. So how deep do you drill the hole so that the

full

diameter depth is correct? Well, you need to know how long the drill

point is.

TIP: The length of the drill point

is

determined by the tool point angle and the drill diameter. You can

calculate the

length of the drill point by multiplying the drill diameter by a

constant; the

value of the constant depends on the drill point angle (most standard

high-speed

steel drills have a tool point angle of 118 degrees).

| For a drill point angle of | Multiply the drill diameter by: |

| 118 degrees | 0.3 |

| 135 degrees | 0.207 |

| 141 degrees | 0.177 |

Using these constants allows you to calculate the drill point length within a few thousandths of an inch.

Spotting Drill

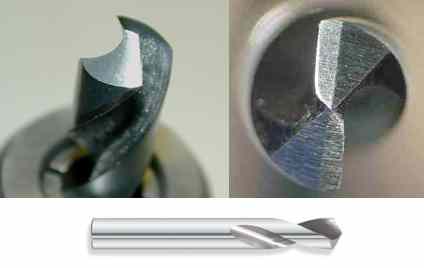

![]() Drills with a standard point (Figure 3) will not be able to center

themselves

when starting a hole. Especially when drilling an uneven surface (like a

cylinder), the drill can “walk” to one side and even break.

Drills with a standard point (Figure 3) will not be able to center

themselves

when starting a hole. Especially when drilling an uneven surface (like a

cylinder), the drill can “walk” to one side and even break.

Figure 3 - A STANDARD POINT DRILL (LEFT) VS. A SPLIT POINT DRILL (RIGHT)

SIDE

VIEW STANDARD (BOTTOM)

Therefore, when using a standard point drill, always use a spotting drill to make a starting mark. The spotting drill ahs shorter flutes & a narrower tip than a standard drill, allowing it to make an accurate impression in the work. The standard drill then starts in that impression, producing an accurate hole.

Reamer

![]() A reamer is designed to remove a small amount of material from a drilled

hole.

The reamer can hold very close tolerance on the diameter of a hole, and

give a

superior surface finish. The hole must be drilled first, leaving 0.005

to 0.015

inch of stock on the walls of the hole for the reamer to remove.

A reamer is designed to remove a small amount of material from a drilled

hole.

The reamer can hold very close tolerance on the diameter of a hole, and

give a

superior surface finish. The hole must be drilled first, leaving 0.005

to 0.015

inch of stock on the walls of the hole for the reamer to remove.

TIP: The ideal situation for hole size accuracy and location when reaming is to process the hole with the following steps: the hole is first drilled, then bored, then reamed.

TIP: Stock allowance for a reamed hole will depend on the size of the hole. A general rule is:

| Holes less than 1/2" | Holes greater than 1/2" |

| Stock less than 0.015" Dia. | Stock of 0.030" Dia. |

The type of workpiece material and the method used to create the hole will affect the stock allowance.

TIP: A reamer produces the best, most uniform surface finish when it is fed into and out of the hole using the G85 (bore in, bore out) canned cycle. Many people try to save time by using the G81 (drill) canned cycle, which will feed into a hole and rapid out. It is quicker than G85, but will usually leave a helical swirl mark on the cylindrical surface of the hole. Although this swirl mark is only a cosmetic flaw and doesn't affect the size of the hole, the appearance of the hole may be rejected by some customers.

Tap

A tap is used to create screw threads inside of a drilled hole. While Automatic Tapping heads for milling machines can automate the tapping of holes, tapping is most cheaply done by hand.

TIP: Tap drill size is the size of the hole required for a specific tap. For 75% effective threads the formula that will determine the correct drill size is:

D – 1/N, where D = major diameter of the tap and N = number of threads per inch

A tapped hole with 75% of thread depth has only 5% less strength than 100% thread and takes only 1/3 of the cutting force of a 100% thread.

End Mills

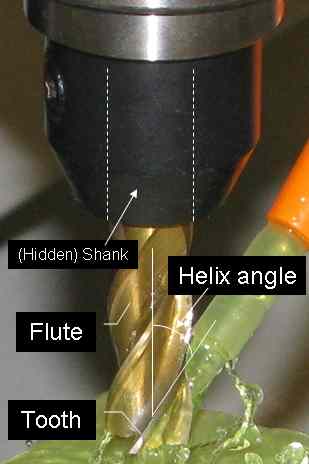

![]() End mills are used for many operations, and come in a variety of shapes

&

sizes.

End mills are used for many operations, and come in a variety of shapes

&

sizes.

Regular or Flat End Mill

![]() Most generic end mill that can be used for many tasks. Bellow is

the

labeled parts of end mills.

Most generic end mill that can be used for many tasks. Bellow is

the

labeled parts of end mills.

Bull End Mill

![]() A bull end mill is the same as a regular end mill except that there is a

radius

on the corner where the flutes meet the bottom of the end mill. This

radius can

be any size up to one-half of the tool's diameter.

A bull end mill is the same as a regular end mill except that there is a

radius

on the corner where the flutes meet the bottom of the end mill. This

radius can

be any size up to one-half of the tool's diameter.

TIP: Bull end mills are effective for producing a corner radius between a wall and a floor on a given part feature. They also add to the strength of an end mill. When machining hard, tough to cut materials, the sharp corners on a standard end mill tend to chip and wear faster than an end mill with a corner radius. The radius on a bull end mill provides a more gradual shearing entry in to the work piece.

Ball End Mill

![]() A

ball end mill is a bull end mill where the corner radius is exactly 1/2

the

tool's diameter. This gives the tool a spherical shape at the tip. It

can be

used to cut with side of the tool like an end mill.

A

ball end mill is a bull end mill where the corner radius is exactly 1/2

the

tool's diameter. This gives the tool a spherical shape at the tip. It

can be

used to cut with side of the tool like an end mill.

TIP: The primary purpose of a ball end mill is to machine lofted surfaces. The spherical shape of the tool is able to move along any undulating surface and cut anywhere along the cutter's "ball end." As a ball can roll over a surface, a ball end mill can be used to cut any such surface.

Special Purpose Tools

|

Corner

-Corner-Rounding End Mill This end mill has a concave tip radius which allows it to round outside edges of work. It can also flare holes, provided the hole is wider than the nose. |

|

Keyseat /

T-slot

Cutter Much like a small saw blade, the teeth of this cutter can cut precise slots more quickly than an end mill. It is used to make keyseats for woodruff keys. Larger versions can be used to cut T slots. |

|

Dovetail

Cutter The 45° or 60° sides of this cutter are used to sidemill dovetails into a work piece. |

|

|

Drill Mill /

Angle End Mill The angled tip of this end mill can be used to chamfer edges, countersink holes, or make shallow grooves. The tip usually has an 82°, 90°, or 100° included angle for countersinking different kinds of flathead screws. |

Section 3 - Operations

Slotting

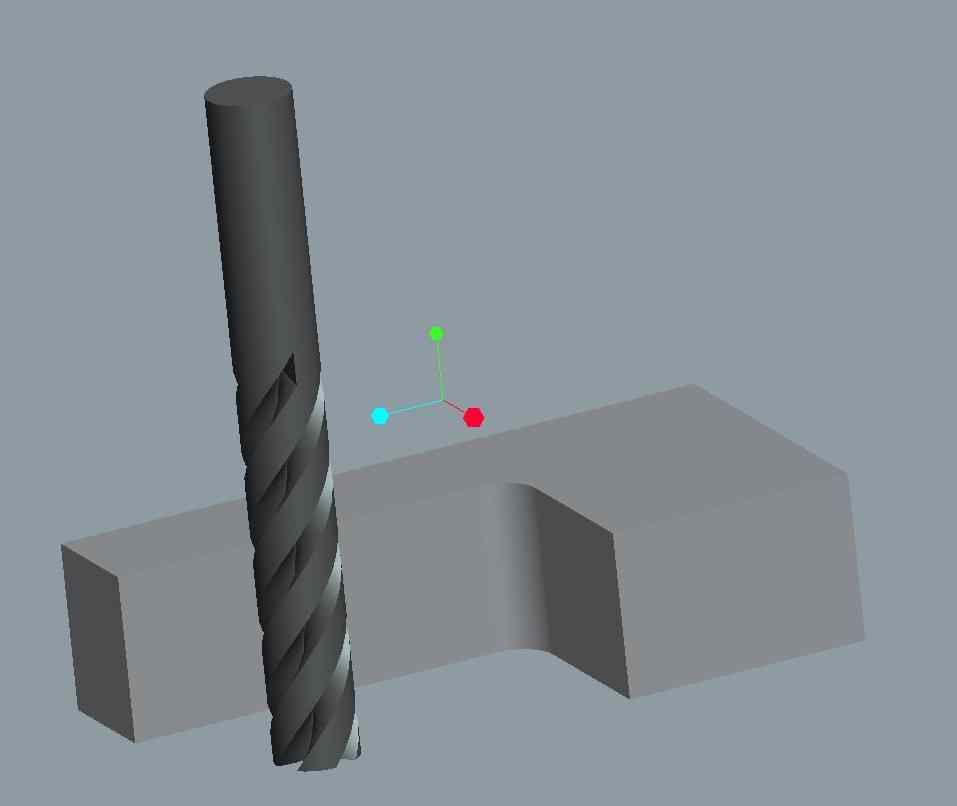

![]() The most common operation for an end mill is slotting (Figure 4).

A single axis move brings the tool into the work, creating a channel

close to

the width of the tool.

The most common operation for an end mill is slotting (Figure 4).

A single axis move brings the tool into the work, creating a channel

close to

the width of the tool.

FIGURE 4 - SLOTTING ALUMINUM WITH AN END MILL

To perform this operation properly:

· Choose a depth of cut no greater than the diameter of the tool

· Use a 2-flute end mill for deep cuts to evacuate chips more easily

· Use coolant for heavy cuts to evacuate chips

Side milling

![]() Any cut using primarily the sharp sides of a milling cutter (end mill,

shell

mill, etc.) is referred to as side milling. With the right combination

of feed &

speed, side milling can produce a finer finish than end milling, since

the

motion of the tooth is more uniform across the work piece.

Any cut using primarily the sharp sides of a milling cutter (end mill,

shell

mill, etc.) is referred to as side milling. With the right combination

of feed &

speed, side milling can produce a finer finish than end milling, since

the

motion of the tooth is more uniform across the work piece.

Most side milling on small machines is performed with an end mill. Cutting forces are higher due to the large area being cut. As such, depth of cut needs to be reduced, and should never exceed the radius of the cutter. Deep & heavy rough cuts will tend to bend the tool away from the work, which makes the cut shallower at the tip of the tool than at the base. Finish passes of about .005” to .010” depth of cut should be used to ensure a perpendicular edge.

Pocketing/Profiling

![]() End mills can also be used to create pockets in a work piece. On a

manual

machine, pockets can be cut only in rectangular/circular shapes.

The precise

control of the X & Y axes on a CNC mill allows pockets of any shape

to be cut

(figure 5). The tool can be fed into the work in either the Z

axis, or one of

the transverse axes. If the end mill is plunged fully into the

work, and then

moved in X& Y axes, then the sides of the teeth perform most of the

cutting. By

taking shallower plunges & larger stopovers, more of the cutting is

performed by

the ends of the mill. Due to the changing directions of cutting

forces during

roughing, a finish pass is necessary to produce a precision surface.

End mills can also be used to create pockets in a work piece. On a

manual

machine, pockets can be cut only in rectangular/circular shapes.

The precise

control of the X & Y axes on a CNC mill allows pockets of any shape

to be cut

(figure 5). The tool can be fed into the work in either the Z

axis, or one of

the transverse axes. If the end mill is plunged fully into the

work, and then

moved in X& Y axes, then the sides of the teeth perform most of the

cutting. By

taking shallower plunges & larger stopovers, more of the cutting is

performed by

the ends of the mill. Due to the changing directions of cutting

forces during

roughing, a finish pass is necessary to produce a precision surface.

Contour

This the process of milling an ill regular surface. This can simply creating an island as seen below in figure 5 or milling more complex curves like letters.

FIGURE 5 - POCKET (LEFT) PROFILE (RIGHT)

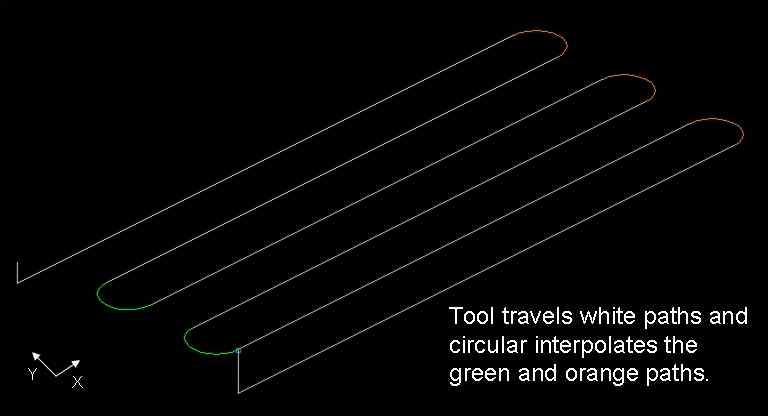

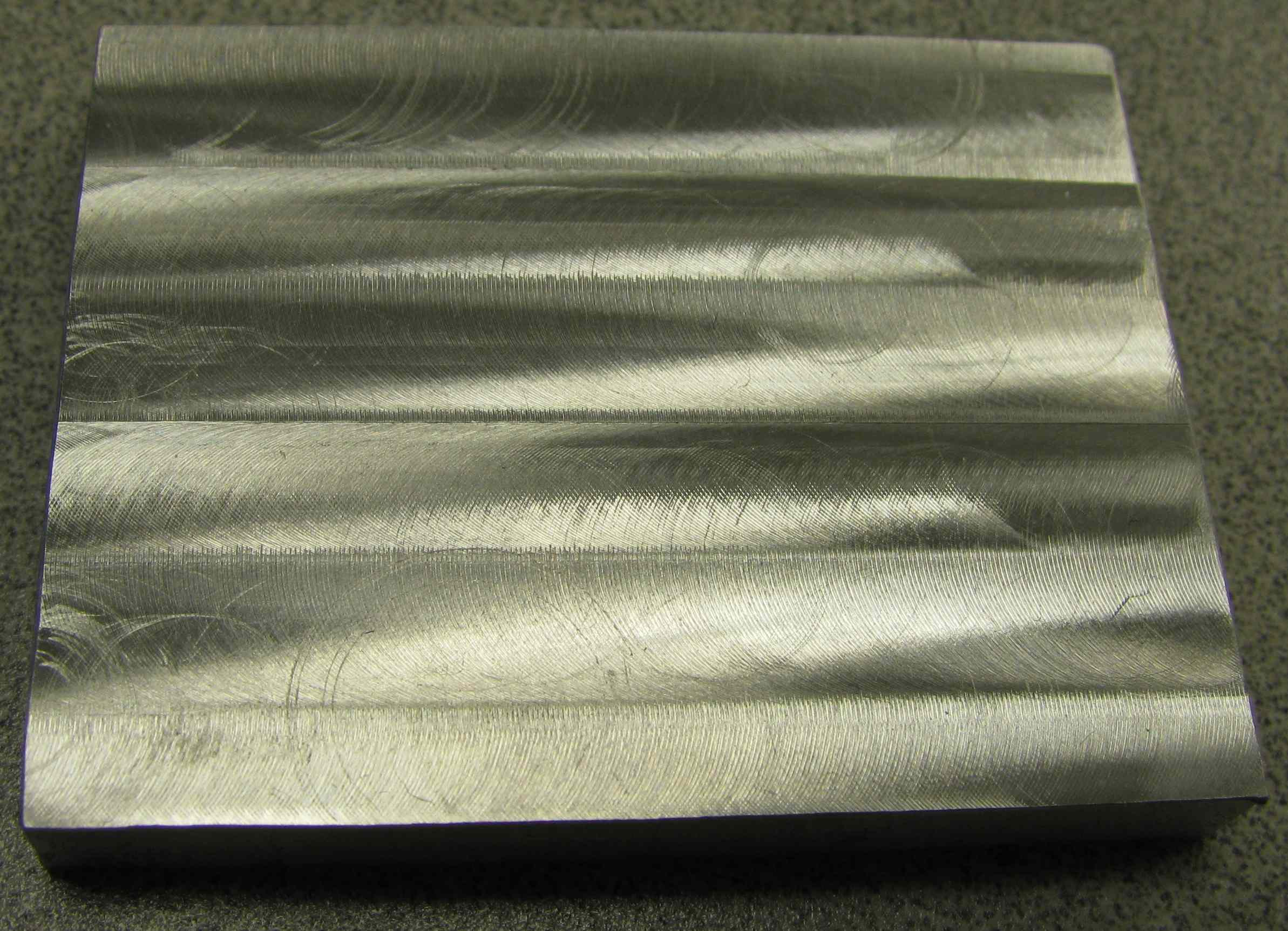

Face Milling

Face Milling uses a face mill to take large sweeps over the surface of the material each pass. Each pass is usually evenly spaced over the surface of the material as shown in the NCplot diagram in figure 6.

FIGURE 6 - FACE MILL NC PATH

The operation usually takes off a few thousands of an inch of material

on the top of the

block for squaring purposes. Also the face mill leaves a clean finish

that can

seen in figure 5 and 7. Figure 5 notice the wide passes uses a 2

carbide

tip

face mill. Figure 7 uses small passes to achieve the same result

but

uses a flat 4 flute end mill.

FIGURE 7 - FLAT 4 FLUTE FACE MILL