|

While the catastrophe of American bombing in 1945 affected all of Japanese industry, Toyota's

biggest crises came about five years later. This financial and labor crisis was the inspiration

for what became the Toyota Production System.

The Toyota Story

|

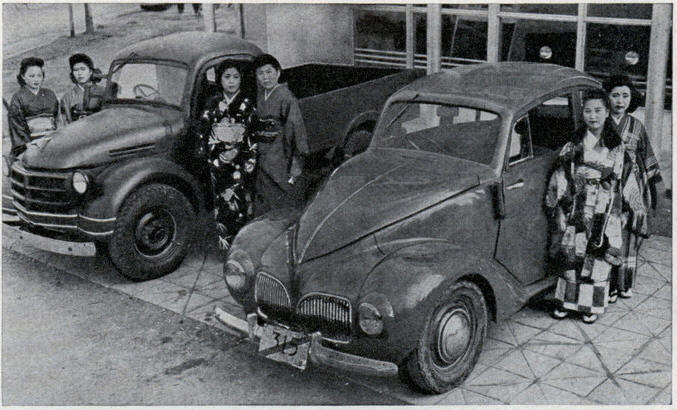

Toyota Lineup for 1947

|

Toyota Motor Company was formed in 1933 as an offshoot of the Toyoda spinning and

Weaving Company. It was the special interest of Kiichiro Toyoda, son of Soichiro Toyoda.

The first Toyota truck was made in 1935 and the first passenger car in 1936. As the Japanese

army began to drag the country into its Manchurian and Chinese adventures, Toyota converted

almost entirely to truck production.

When World War II ended Toyota had 3000 employees and no working facilities. The economy was

in chaos. Nevertheless, Toyota designed a new postwar automobile in 1947 and attempted to

rebuild the firm.

The Japanese economy continued to suffer and by 1949 raw materials and goods of all kinds

were still in short supply. Inflation was rampant, and urban dwellers often traded clothing and

furnishings for rice or potatoes. In 1949 the government took drastic measures to control

runaway inflation. The anti-inflationary measures reduced consumer demand and totally dried up

commercial credit. Toyota's financial situation then deteriorated rapidly. Toyota could not meet

payroll.

|

A Note On This Article

There seems to be no comprehensive, rigorous and documented history of Toyota or its

principle personalities in the way that Robert Lacey and others have written about Ford

Motor and the Ford family.

The accounts of Toyota's history that do exist tend to be fragmentary, general and

sometimes contradictory. Take, for example, the Ford influence on Toyota. I have read

that it was Taiichi Ohno who visited the Ford factories and brought back Ford's

production concepts. Other accounts have Kiichiro Toyoda visiting River Rouge in 1933

(or 1929) and while others say it was Eiiji Toyoda who visited Ford after World War II.

Most likely, both Kiichiro and Eiji made such visits but not Ohno.

The account given here was derived from many sources, some forgotten and all suffering

from the lack of rigor, research and citation noted above. Some facts and statements may

therefore be incorrect. Nevertheless, it is a good story and correct in spirit if not in

specifics.-- Q. Lee

|

|

|

Kiichiro Toyoda

|

Toyota's labor union went on strike in April of 1949 over impending layoffs. The strike

was bitter and negotiations dragged on until bankruptcy was imminent. In the end management and

labor agreed to reduce the workforce from 8,000 to 6,000 employees. President Kiichiro Toyoda

and his executive staff resigned.

After the strike, two of the company’s new executives, Eiji Toyoda (now chairman of Toyota

Motor Corporation) and Shoichi Saito, visited the United States seeking new ideas. According to

legend he conceived the Kanban idea from observing American supermarkets. Ford Motor Company

certainly had a major influence.

|

Eiiji Toyoda

|

Another legend has Eiiji asking his lieutenants why they needed inventory. There

were, of course many reasons. Eiiji's response was "Now, please eliminate those

reasons." Eiiji recognized that inventory was the footprints left by problems and simply

covered up the problems rather than permanently solving them.

Taiichi Ohno was put in charge of implementing the new ideas that evolved into the Toyota

Production System. Ohno had a reputation for being undiplomatic (almost ruthless) but he got

things done.

Taiichi Ohno

|

He hired Shigeo Shingo to first work on the setup reduction problem. Shingo was

spectacularly successful and the solutions became the famous SMED system. It is likely

that Shingo was responsible for many of the technical innovations and production ideas

that evolved at Toyota.

In the years after the war, Japan was mostly governed by General MacAurthur's occupation

staff. In an attempt to distribute power more broadly in Japanese society, MacAurthur's staff

encouraged labor unions and greatly strengthened them. Toyota management may not have fully

appreciated the new power of the labor union, thus helping to provoke the strike. Whatever the

reason, the strike must have had a profound affect on Toyota's approach to employees. There has

never been another strike.

Toyota's Learning Experience

Toyota emerged from World War II as a small manufacturer of third-rate cars in a backwater

market. Today they are challenging General Motors for the position of largest vehicle

manufacturer in the world.

The turning point seems to have come with the financial and labor crises of 1949-1950. The

crisis led to a paradigm shift about the role of people in Toyota's operations and this was more

important even than the many process and technical innovations that all became part of the

Toyota Production System and Lean Manufacturing.

|