|

Lean

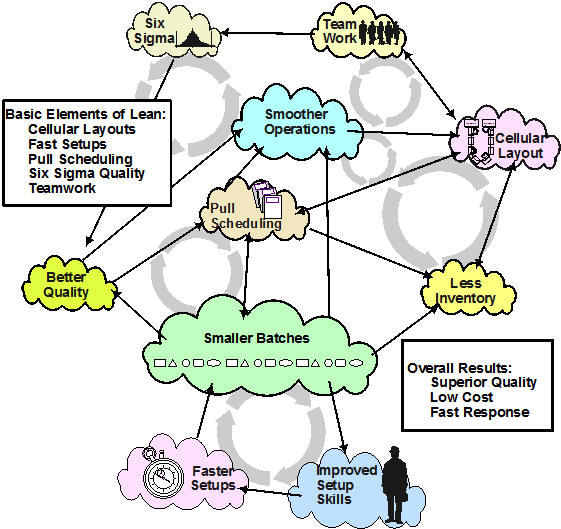

Manufacturing systems have interrelated elements that form a system or Manufacturing Strategy.

The graphic shows how these elements work together and reinforce each other. Each arrow

indicates a positive influence or relationship. For example, Fast Setups enable small batches,

and small batches result in smoother material flows. Note the number of circular loops. Such

loops continuously reinforce each other driving the system to higher and higher levels of

performance--like a snowball rolling downhill. Lean

Manufacturing systems have interrelated elements that form a system or Manufacturing Strategy.

The graphic shows how these elements work together and reinforce each other. Each arrow

indicates a positive influence or relationship. For example, Fast Setups enable small batches,

and small batches result in smoother material flows. Note the number of circular loops. Such

loops continuously reinforce each other driving the system to higher and higher levels of

performance--like a snowball rolling downhill.

These effects are part of a body of knowledge known as "System Dynamics", "Industrial

Dynamics", or just "Systems Theory". A factory system has both technical and human elements

which immensely complicates theoretical analysis. Moreover, such systems may exhibit very

strange behavior such as instability and chaos. Lean Manufacturing addresses many of the

elements that reduce chaotic effects such as variability, time delays and complexity.

It is difficult to study such systems directly since their complexity makes modeling

difficult. Our understanding generally comes from working with simpler models and extrapolating

the results through intuition and general principles. For a complete discussion of these systems

and related phenomena, go to "Principia

Cybernetica Web".

|

|