How It Works

Kanban

scheduling systems operate like supermarkets. A small

stock of every item sits in a dedicated location with a

fixed space allocation. Customers come to the store and

visually select items. An electronic signal goes to the

supermarket's regional warehouse detailing which items

have sold. The warehouse prepares a (usually) daily

replenishment of the exact items sold.

In modern

supermarkets Kanban signals come from checkout scanners.

They travel electronically (usually once a day) to the

warehouse. Smaller stores still use visual systems.

Here, a clerk walks the aisles daily. From empty spaces

he deduces what sold and orders replacements.

Another variation is the bread truck. Here drivers

follow a fixed route from store to store. They have a

supply of bakery items in their truck. At each stop,

they examine the stock and replenish what has been sold.

Kanban scheduling in

manufacturing works in the same way. The essential

elements of a system are:

-

Stockpoint(s)

-

A

Withdrawal Signal

-

Immediate

Feedback

-

Frequent

Replenishment

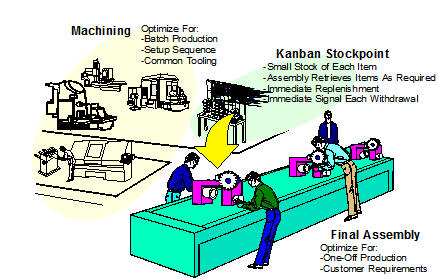

Kanban Schematic

This graphic illustrates how a Kanban system

connects the upstream supplier or workcenter with a downstream user or customer. It

operates through a small stockpoint and a signaling system.

|

|

|

Kanban In A

Supermarket

The entire buy-replenishment cycle is 1-3 days.

Supermarkets have the highest inventory turnover of almost any business. One of several

legends says that the supermarket was the original inspiration for Kanban.

|

|

Kanban In Manufacturing

Here, the supermarket principle is applied to a

machining and assembly operation. Machining and assembly have very different

requirements and considerations for scheduling. Kanban compensates for these differing

requirements.

|

|